January 12, 2026

10 Process Improvement Best Practices for Operations and Support Teams in 2026

Discover 10 actionable process improvement best practices. Learn key frameworks, KPIs, and change management tips to drive efficiency and consistency.

In today's competitive business environment, stagnant workflows are silent killers of productivity and customer satisfaction. While teams in agencies, customer success, operations, and product development are busier than ever, they often operate on outdated, unwritten 'tribal knowledge' processes. This reliance on "how we've always done it" leads to inconsistency, critical errors, and wasted resources that directly impact your bottom line. The solution isn't just working harder; it's working smarter by systematically refining how work gets done.

Adopting proven process improvement best practices transforms these chaotic, ad-hoc workflows into scalable, efficient systems that drive growth. This guide cuts through the noise to provide a prioritized, actionable roundup of strategies designed for immediate impact. We will cover the essential pillars of a robust process framework, from foundational documentation and KPI measurement to advanced change management and intelligent automation.

You will learn how to:

Establish a single source of truth for all critical procedures.

Engage stakeholders to ensure buy-in and successful adoption.

Measure what matters to track progress and identify bottlenecks.

Build a culture of continuous improvement that prevents stagnation.

These strategies provide concrete playbooks that turn abstract theory into day-to-day practice. By implementing these tactics, your team can eliminate operational friction, improve service delivery, and build a resilient foundation for sustainable growth. Let's dive into the core practices that will transform your operations.

1. Document Processes Before Optimizing Them

The most critical first step in any process improvement initiative is to resist the urge to immediately change things. Instead, start by meticulously documenting the current state of your workflows exactly as they happen today. This 'as-is' documentation creates an essential, unbiased baseline that serves as the foundation for all future optimization efforts. Without a clear picture of the starting point, it's impossible to measure the impact of changes, identify the true sources of inefficiency, or ensure that critical steps aren't accidentally discarded during redesign.

This foundational practice, championed by pioneers like W. Edwards Deming and central to methodologies like Lean and Six Sigma, is about capturing reality, not theory. For instance, a ServiceNow customer might use screen recordings to document the entire IT ticketing lifecycle before implementing automation, revealing hidden bottlenecks that interviews alone would miss. Similarly, consulting firms like Accenture often begin engagements by mapping a client's existing processes, which once revealed that 23% of a financial service firm's manual tasks were prime candidates for automation, a discovery only possible after capturing the actual workflow.

How to Implement This Practice

Creating an accurate baseline is one of the most vital process improvement best practices because it replaces assumptions with data. The goal is to capture what people actually do, not what the old SOP says they should do.

Use Screen Recording Tools: Capture processes in real-time to get an unfiltered view. This eliminates recall bias and captures the nuances, workarounds, and informal steps that employees use every day.

Document Multiple Instances: Record the same process being performed by different team members or at different times. This helps identify variations and inconsistencies that need to be standardized.

Involve Process Owners: Have the employees who perform the work review the documented processes for accuracy. They can confirm steps, explain their reasoning for deviations, and point out crucial edge cases.

Create a Centralized Library: Store your 'as-is' process documentation in a version-controlled repository. This creates a historical record that can be referenced when evaluating future improvements or troubleshooting issues.

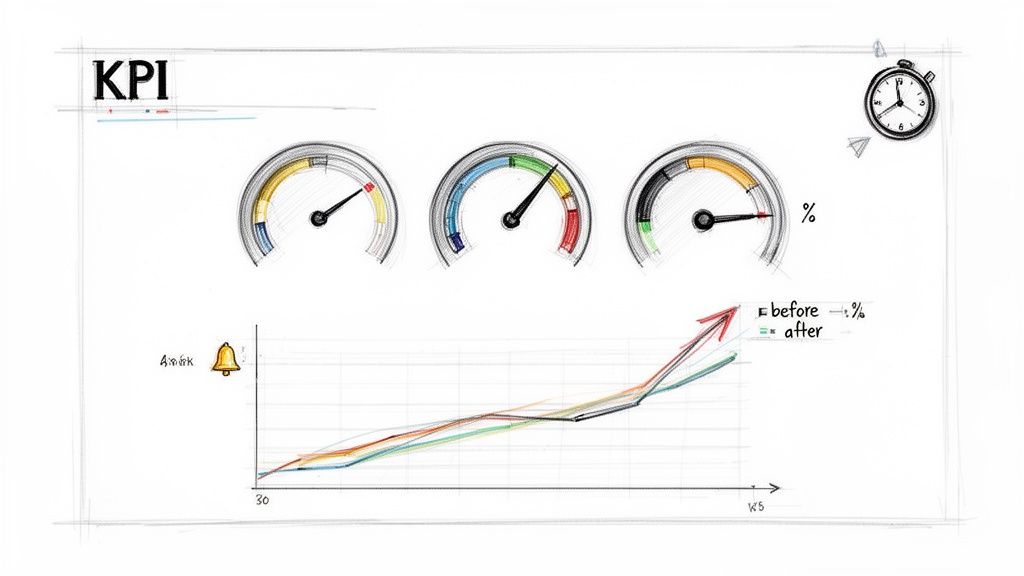

2. Implement Continuous Process Monitoring and Metrics

Process improvement is not a one-time project; it's a continuous cycle. To move from isolated fixes to sustainable optimization, you must implement ongoing monitoring with clear metrics. This practice shifts the focus from a single 'before-and-after' snapshot to a dynamic, real-time understanding of performance. By tracking key performance indicators (KPIs), you can measure the true impact of changes, catch deviations before they become major problems, and make data-driven decisions for future enhancements.

This philosophy, heavily influenced by figures like Peter Drucker who famously stated, "You can't manage what you don't measure," is about embedding analytics into your operations. For example, Amazon constantly monitors thousands of process metrics in its fulfillment centers, using this data to A/B test even minor workflow adjustments before a global rollout. Similarly, Walmart leverages real-time inventory and logistics metrics to optimize its complex supply chain, ensuring products move efficiently from warehouse to shelf. This data-first approach transforms process management from a reactive exercise into a proactive strategy.

How to Implement This Practice

Establishing a system for continuous measurement is one of the most powerful process improvement best practices as it validates your efforts with objective data. This creates a feedback loop where you can see precisely what’s working and what isn’t, allowing for rapid iteration.

Start with Critical Metrics: Avoid analysis paralysis by selecting just 3-5 crucial KPIs that directly reflect the process's health, such as cycle time, error rate, or customer satisfaction scores.

Establish a Clear Baseline: Before implementing any changes, measure and document your chosen metrics over a set period. This baseline is the benchmark against which all future performance will be compared.

Create Visual Dashboards: Make performance data accessible and understandable to the entire team using simple, visual dashboards. This promotes transparency and keeps everyone aligned on performance goals.

Set Measurable Targets: Define specific, time-bound improvement goals, for example, "achieve a 15% reduction in customer ticket response time within Q3." This provides a clear target for the team to work towards.

Use Metrics to Celebrate Wins: When metrics show improvement, share these successes with the team. Celebrating data-backed wins builds momentum and reinforces the value of the continuous improvement culture.

3. Engage Stakeholders and Process Owners Early

Process improvement initiatives that are dictated from the top down often fail because they lack crucial frontline context and buy-in. A core best practice is to engage stakeholders and process owners from the very beginning. This collaborative approach ensures that any proposed changes are grounded in practical reality, not just theoretical efficiency. Involving the people who actually perform the work builds a sense of ownership, dramatically increases adoption rates, and uncovers nuanced insights that leadership would otherwise miss.

This principle is a cornerstone of methodologies popularized by figures like Taiichi Ohno with the Toyota Production System and is central to Agile and Lean Startup philosophies. For example, Toyota's famous kaizen (continuous improvement) culture empowers every employee, from the assembly line to the executive suite, to suggest and implement improvements. Similarly, Zappos actively involves its customer service representatives in redesigning support workflows, which has led to nearly universal adoption of new processes because the team co-created them. These examples prove that when people are part of the solution, they become champions for the change.

How to Implement This Practice

Engaging your team is one of the most effective process improvement best practices because it transforms a top-down mandate into a shared, bottom-up mission. The goal is to make improvement a collaborative effort, not an imposed one.

Hold Kickoff Meetings: Before any analysis begins, bring together all stakeholders, including process owners, end-users, and managers from affected departments. Clearly communicate the project's goals and emphasize their critical role in its success.

Facilitate Collaborative Validation: Invite the primary process owners to review and validate the documented "as-is" workflows. They are the ultimate source of truth and can instantly spot inaccuracies or explain the logic behind certain workarounds.

Create Feedback Channels: Establish clear and simple channels like a dedicated Slack channel or a shared document for team members to provide continuous input as processes are analyzed and redesigned.

Co-create the Solution: Instead of presenting a finished solution, run workshops or brainstorming sessions where stakeholders can contribute ideas for the "to-be" process. This co-creation is the key to building genuine buy-in and ownership.

4. Standardize Processes and Create Single Sources of Truth

Once you have documented your 'as-is' processes, the next step is to eliminate variability. Inconsistent process execution introduces inefficiencies, quality control issues, compliance risks, and unpredictable customer experiences. Standardization involves defining one official, best-practice method for performing a task and ensuring everyone follows it, creating a single source of truth that eliminates tribal knowledge and conflicting guidance. This is foundational for scalability and continuous improvement.

This principle is the bedrock of frameworks like ISO 9001 and is central to the success of massive-scale operations. For example, McDonald's maintains precise consistency across over 40,000 locations using detailed, standardized operation manuals for everything from food preparation to customer service. Similarly, HubSpot created a centralized playbook library for its 7,000+ employees, which improved process consistency by 34% by providing one reliable place for answers. This approach transforms chaotic, ad-hoc workflows into reliable, repeatable business functions.

How to Implement This Practice

Creating a single source of truth is one of the most powerful process improvement best practices because it establishes a stable foundation for measurement, training, and automation. It ensures that improvements benefit the entire organization, not just one person.

Prioritize High-Impact Processes: Begin by standardizing the processes that are performed most frequently or have the greatest impact on customers and revenue. This delivers the fastest return on your documentation effort.

Document the 'Why': Don't just list the steps; explain the reasoning behind them. This context helps teams understand the importance of each action and encourages better adherence.

Establish a Centralized Hub: Use a dedicated platform or branded hub to house all your Standard Operating Procedures (SOPs). Organize them by department or function so employees can easily find what they need. You can get started with a standard operating procedure template to structure your documentation effectively.

Implement Version Control: Ensure your process hub has clear version control so that team members are always accessing the most current, approved guide. This prevents outdated information from causing errors.

Create an Approval Workflow: Define a clear process for how new standards are reviewed, approved, and published. This maintains the integrity and quality of your single source of truth.

5. Use Visual Process Documentation and Provide Continuous Training

Static, text-only procedure documents are ineffective for modern workflows. The most impactful process improvement best practices combine visually-rich, step-by-step documentation with a commitment to continuous training. Visual guides with screenshots, callouts, and videos are processed by the human brain 60,000 times faster than text, leading to faster comprehension and fewer errors. However, creating a guide is only half the battle; ensuring team members master and retain the process requires ongoing reinforcement and just-in-time support.

This dual approach, popularized by companies like Apple and modern SaaS onboarding playbooks, ensures processes are not only well-defined but also consistently executed. For instance, Slack’s visually-driven onboarding guides helped reduce new user support tickets by 40%. Similarly, Starbucks invests over 20 hours of hands-on training for every new barista on its visually documented core processes, achieving 95% consistency across thousands of locations. This proves that documentation and training are two sides of the same coin, critical for embedding improvements into daily operations.

How to Implement This Practice

Combining clear visuals with ongoing learning is one of the most effective process improvement best practices because it addresses both knowledge transfer and skill retention. The goal is to make correct execution the easiest path for employees, both during initial onboarding and in their daily work.

Create Visually-Rich Guides: Capture actual screen recordings of a process to generate step-by-step guides. Use annotations like arrows, highlights, and red boxes to direct user attention to critical elements. Learn more about how to create a step-by-step guide for maximum clarity.

Structure for Comprehension: Keep each guide focused, ideally between 5-7 steps. Use action-oriented headers for each step (e.g., "Click the 'Submit' Button") and add contextual tips or warnings as callouts.

Implement Continuous Training: Make training materials accessible and consumable in short, 5-15 minute micro-learning sessions. Use interactive video walkthroughs, real-world scenarios, and spaced repetition to reinforce key concepts.

Provide Just-in-Time Support: Store all visual guides and training modules in a centralized, easily searchable library. This allows team members to quickly find the exact guidance they need while performing a task, rather than having to recall it from a past training session.

6. Establish Clear Process Ownership and Accountability

A documented process without a dedicated owner is an orphan workflow destined for neglect and decay. Assigning clear ownership is the practice of designating a specific individual responsible for a process's performance, maintenance, and continuous improvement. This owner acts as the single point of accountability, ensuring that the process remains effective, relevant, and aligned with business goals. Without an owner, improvements are often temporary, responsibility becomes diffused, and vital processes stagnate.

This principle is a cornerstone of effective management systems like ISO 9001 and is famously exemplified by Amazon's "single-threaded leaders" model, where individuals are given end-to-end ownership of a single major initiative to drive focus and accelerate progress. Similarly, Netflix assigns dedicated owners to critical customer workflows who are responsible for reporting on process metrics during quarterly business reviews. This accountability structure transforms process improvement from a sporadic project into a continuous, owned business function.

How to Implement This Practice

Establishing clear roles is one of the most impactful process improvement best practices because it creates a direct line of responsibility for results. The process owner is the champion who ensures optimizations are implemented and sustained.

Document Ownership Clearly: Explicitly name the process owner in your central SOP library or process repository. This eliminates any ambiguity about who is responsible for a given workflow.

Select Owners Based on Expertise: Choose individuals who deeply understand the process and possess a mindset geared toward improvement. They should be empowered to make decisions and drive change.

Set Specific Performance Targets: Define and assign measurable KPIs for each process. The owner should be accountable for hitting these targets, such as reducing cycle time or improving first-contact resolution.

Schedule Regular Process Reviews: Create a recurring meeting cadence (e.g., monthly) for process owners to discuss performance, challenges, and potential improvements. This fosters a culture of proactive optimization.

7. Implement Process Automation for High-Volume Repetitive Tasks

Once a process is documented, analyzed, and optimized, the next logical step is to automate high-volume, repetitive activities. Automation uses technology like Robotic Process Automation (RPA) and workflow tools to execute rule-based tasks that previously required human intervention. This frees up team members from mundane work, allowing them to concentrate on strategic, creative, and customer-facing activities that add genuine value. The core principle is simple: first improve the process, then automate it. Automating an inefficient workflow only makes a bad process run faster.

This practice is championed by automation leaders like UiPath and workflow integrators such as Zapier. For example, UiPath customers frequently automate invoice processing, slashing manual data entry by over 70% and reducing cycle times from days to just hours. Similarly, a Deloitte implementation of RPA for a financial services client cut data entry processing costs by 60%. These examples highlight how automation reduces human error, accelerates operations, and delivers significant ROI when applied to the right tasks.

How to Implement This Practice

Applying automation is one of the most impactful process improvement best practices because it directly replaces manual effort with machine speed and accuracy. The key is to select the right candidates for automation and manage the transition effectively.

Target Rule-Based, High-Volume Tasks: Start by identifying processes that are standardized, frequent, and follow clear, logical rules. Think data entry, report generation, or initial customer support ticket routing.

Calculate ROI Before Investing: Before committing to a tool, calculate the potential return on investment. Factor in the cost of software, implementation, and maintenance against the savings from reduced labor hours and increased accuracy.

Involve Technical Teams Early: Engage your IT or development teams from the beginning to ensure the chosen automation solution integrates with your existing tech stack and meets security standards.

Plan for Change Management: Communicate clearly with your team about how automation will change their roles. Emphasize that the goal is to augment their capabilities, not replace them, by shifting their focus to higher-value work.

8. Create Role-Based Documentation for Different User Groups

A one-size-fits-all approach to process documentation often fails because different users have vastly different needs. Creating role-based or audience-specific documentation ensures that every user receives information tailored to their context, skill level, and objectives. This practice improves relevance, accelerates learning, and reduces the cognitive load required to understand and execute a process correctly. Instead of forcing everyone through the same dense manual, you provide focused guides that get straight to the point for each specific audience.

This user-centric approach is a cornerstone of effective SaaS onboarding and technical writing. For instance, GitHub offers distinct documentation paths for developers, enterprise administrators, and casual users, recognizing that their goals and technical expertise vary widely. Similarly, HubSpot provides customer guides segmented by user experience level, ensuring a new user isn't overwhelmed while an expert can quickly find advanced features. This segmentation directly translates to faster adoption, higher proficiency, and fewer support tickets.

How to Implement This Practice

Tailoring documentation is one of the most impactful process improvement best practices for scaling knowledge transfer effectively. It transforms generic instructions into a personalized, high-value resource that respects the user's time and role.

Identify Key User Personas: Start by defining your primary audiences. Common personas include new hires, experienced team members, managers, administrators, and external customers.

Create a Core "Standard" Version: Develop a foundational guide that covers the essential, universal steps of the process. This becomes the base from which you create specialized versions.

Build Role-Specific Variations: Layer on additional details, permissions, or advanced steps for specific roles. For example, a manager's guide might include sections on reporting and team oversight, while an admin's guide covers configuration settings.

Use Clear Labeling: Clearly title each document so users can self-select the correct one (e.g., "Onboarding Guide for New Sales Reps" vs. "Onboarding Guide for Sales Managers").

Test with Actual Users: Before finalizing, have individuals from each persona group review their specific documentation to confirm it is clear, accurate, and meets their needs.

9. Build a Culture of Continuous Improvement and Experimentation

The most sustainable process improvements aren't one-off projects; they are the result of an organizational culture where optimization is an ongoing, collective responsibility. This means shifting from a top-down, project-based approach to a mindset where every employee is empowered to identify and suggest enhancements. Building a culture of continuous improvement, often called kaizen, treats processes as living systems that must constantly evolve based on data, feedback, and new insights. It requires psychological safety for experimentation, clear channels for ideas, and unwavering leadership commitment.

This philosophy is the engine behind some of the world's most innovative companies. Toyota’s famous kaizen approach, for example, generates over a million improvement suggestions from employees annually, treating small, incremental changes as the key to long-term success. Similarly, Amazon's leadership principle of "Customer Obsession" drives constant process refinement at every level, as teams are always looking for better ways to serve the customer. This cultural foundation turns process improvement from a task into a shared value.

How to Implement This Practice

Cultivating this mindset is one of the most powerful process improvement best practices because it transforms your entire workforce into an engine for innovation. The goal is to make improvement a daily habit, not a rare event.

Create Psychological Safety: Explicitly reframe failures as valuable learning opportunities. Leaders should celebrate "intelligent failures" where a well-reasoned experiment didn't work, as this encourages risk-taking and honesty.

Establish Clear Feedback Channels: Implement a simple, visible system for submitting improvement suggestions, whether it's a dedicated Slack channel, a form, or a physical board. Crucially, guarantee a quick response to every idea, even if it's not implemented.

Use Quick PDCA Cycles: Test small changes using the Plan-Do-Check-Act cycle. This allows teams to quickly validate ideas with minimal risk before committing to a full-scale rollout.

Make Improvement Visible: Celebrate and share the results of successful process improvements transparently across the organization. This builds momentum and shows that employee contributions have a real impact on the business. For more ideas on how to foster this engagement, learn about keeping SOPs updated without meetings.

10. Establish Change Management and Communication Protocols

Even the most brilliant process redesign will fail if the people executing it are not brought along for the journey. Effective change management is the bridge between a new, optimized process on paper and its successful adoption in practice. It involves a structured approach to informing, preparing, and supporting teams through the transition to ensure changes are embraced rather than resisted. Without clear communication protocols, improvements can cause confusion, lower morale, and ultimately fail to deliver their intended value.

This discipline, formalized by experts like John Kotter and frameworks like Prosci's ADKAR model, treats the human element of process improvement with the same rigor as the technical analysis. For example, Salesforce manages its frequent platform updates with staged rollouts and detailed communication plans, using advisory boards to gather feedback and smooth adoption. Similarly, Bank of America successfully used a structured change management methodology to implement major process overhauls, reducing implementation failures from a staggering 40% to just 5% by focusing on stakeholder alignment and support.

How to Implement This Practice

Integrating change management is one of the most crucial process improvement best practices because it ensures the theoretical gains of a new process are realized in the real world. The focus is on proactive, empathetic communication and support.

Communicate the 'Why' Before the 'What': Start by explaining the reasons behind the change. When employees understand the problems being solved or the goals being pursued, they are more likely to support the new process.

Segment and Tailor Communication: Identify all stakeholder groups affected by the change. Craft specific messages for each group that address their unique concerns and highlight the benefits most relevant to their roles.

Provide Ample Advance Notice: Give teams at least two to four weeks of notice for significant process shifts. This prevents them from feeling blindsided and gives them time to ask questions and prepare.

Offer Proactive Training and Support: Schedule training sessions, create FAQ documents, and offer office hours before the new process goes live. Ensure everyone feels confident and equipped to succeed from day one.

Designate 'Change Champions': Identify influential team members to act as advocates for the new process. These champions can provide peer support, answer questions, and relay feedback from the front lines to leadership.

10-Point Process Improvement Comparison

Practice | 🔄 Implementation complexity | ⚡ Resource requirements & speed | ⭐ Expected effectiveness | 📊 Expected outcomes | 💡 Ideal use cases / tips |

|---|---|---|---|---|---|

Document Processes Before Optimizing Them | 🔄 Medium — observation, interviews, mapping effort | ⚡ Moderate time; needs screen-recording tools and stakeholder time | ⭐ High — creates reliable baseline for decisions | 📊 Baseline metrics, gap identification, fewer missed steps | 💡 Use screen recordings; document multiple instances and edge cases |

Implement Continuous Process Monitoring and Metrics | 🔄 High — analytics, KPI design, dashboarding | ⚡ Requires monitoring tools and analyst time; enables real-time alerts | ⭐ Very high — enables data-driven ongoing improvements | 📊 Early issue detection, measurable ROI, rapid course-correction | 💡 Start with 3–5 KPIs; create visual dashboards and set targets |

Engage Stakeholders and Process Owners Early | 🔄 Medium — coordination and facilitation across teams | ⚡ Low–moderate tooling; higher upfront meeting time | ⭐ High — increases adoption and practical applicability | 📊 Greater buy-in, fewer implementation failures, better solutions | 💡 Hold kickoff meetings; co-edit guides; solicit frontline input |

Standardize Processes and Create Single Sources of Truth | 🔄 High — governance, templates, version control required | ⚡ Significant upfront effort; efficient at scale | ⭐ Very high — improves consistency and scalability | 📊 Reduced errors, faster onboarding, stronger compliance | 💡 Start with high-impact processes; enforce version control and approvals |

Use Visual Process Documentation and Provide Continuous Training | 🔄 Medium — content creation and ongoing updates | ⚡ Higher initial production effort; accelerates training speed | ⭐ Very high — boosts comprehension and retention | 📊 Faster proficiency, fewer support tickets, improved compliance | 💡 Capture real screen recordings; keep guides 5–7 steps; use microlearning |

Establish Clear Process Ownership and Accountability | 🔄 Low–Medium — assign roles and governance | ⚡ Low tooling; requires role time and periodic reviews | ⭐ High — ensures maintenance and continuous improvement | 📊 Clear accountability, sustained process health, faster fixes | 💡 Document owners in SOPs; set targets and create backups |

Implement Process Automation for High-Volume Repetitive Tasks | 🔄 High — technical design, integration, exception handling | ⚡ Significant investment and setup; very fast runtime efficiency | ⭐ High for rule-based tasks; limited for judgment work | 📊 Large time/cost reductions, 24/7 execution, improved accuracy | 💡 Optimize process first; automate standardized, high-volume tasks |

Create Role-Based Documentation for Different User Groups | 🔄 Medium — persona mapping and multiple versions | ⚡ Moderate content effort; improves onboarding speed | ⭐ High — increases relevance and engagement | 📊 Higher adoption, reduced support volume, faster learning | 💡 Identify personas; publish basic/intermediate/advanced versions |

Build a Culture of Continuous Improvement and Experimentation | 🔄 High — cultural change, leadership modeling needed | ⚡ Long-term investment; experiments can run quickly | ⭐ Very high — drives sustained innovation and resilience | 📊 Continuous improvement pipeline, higher engagement, innovation | 💡 Provide suggestion channels, run quick PDCA cycles, celebrate wins |

Establish Change Management and Communication Protocols | 🔄 Medium — planning, stakeholder impact analysis, timelines | ⚡ Requires coordinated communication and training time | ⭐ High — reduces resistance and rollout risk | 📊 Smoother transitions, higher adoption, fewer rollbacks | 💡 Explain "why" first; tailor messages; provide training and FAQs |

From Documenting to Dominating: Your Next Move

The journey through the landscape of process improvement best practices reveals a fundamental truth: operational excellence is not a destination, but a continuous cycle of refinement. We've navigated the essential pillars, from the foundational act of documenting processes before optimizing them to the cultural shift required to build an environment of perpetual enhancement. The path to mastery isn't about a single, revolutionary change; it's about the cumulative impact of consistent, intelligent adjustments.

By embracing these principles, you are equipping your organization to move beyond reactive problem-solving. Instead of merely extinguishing fires, you are building a resilient, fire-resistant structure. You are creating a system where clarity replaces ambiguity, and proactive improvement becomes the default operational mode, not a special project. This is the core of sustainable growth.

Synthesizing Your Strategy: Key Takeaways

The ten best practices we've discussed are interconnected, forming a powerful framework for transformation. Let's distill them into a cohesive strategy. Think of it as a three-part blueprint for action: Foundation, Engagement, and Evolution.

Your Foundation is Clarity: The non-negotiable starting point is creating a single source of truth. Practices like documenting processes first (#1), standardizing them (#4), and using visual documentation (#5) create the stable ground upon which all other improvements are built. Without this baseline, you are operating on assumptions, and your efforts to measure or enhance will be fundamentally flawed.

Your Engine is Engagement: A process is only as strong as the people who execute it. This is why engaging stakeholders (#3), establishing clear ownership (#6), and building robust change management protocols (#10) are critical. These practices transform process improvement from a top-down mandate into a collaborative, shared mission, ensuring buy-in and accountability across every team.

Your Future is Evolution: Static processes lead to stagnation. The most successful organizations treat their operations as a living system. By implementing continuous monitoring (#2), leveraging automation (#7), and, most importantly, fostering a culture of continuous improvement (#9), you create a feedback loop. This loop ensures your processes don't just solve today's challenges but are agile enough to adapt to tomorrow's opportunities.

Your Actionable Next Steps: From Theory to Reality

Reading about process improvement best practices is insightful, but implementing them is what drives results. The leap from knowledge to action can feel daunting, so here is a concrete plan to get you started this week:

Select One High-Impact, Low-Complexity Process: Don't try to boil the ocean. Choose a single workflow that is frequently used but causes friction. This could be client onboarding, a specific customer support ticket category, or a new employee setup checklist.

Document It "As Is": Use a screen recording tool to capture the process exactly as it is performed today, warts and all. The goal is not perfection but an honest snapshot of reality. This simple act immediately establishes your baseline.

Identify One Point of Friction: Review the documented process with a key stakeholder. Ask a simple question: "What is the single most frustrating or time-consuming step in this workflow?" This identifies your first target for improvement.

Implement and Communicate One Small Change: Propose a minor adjustment to address that point of friction. It could be automating a single data entry step, clarifying a confusing instruction, or creating a simple template. Communicate this change clearly to the team involved.

By following these four steps, you initiate the cycle of improvement in a manageable, low-risk way. You build momentum and demonstrate the tangible value of this methodology, making it easier to gain support for larger initiatives. This approach transforms the abstract concept of process improvement into a real, observable win for your team. This is how a culture of excellence begins: not with a grand announcement, but with a single, well-executed step forward.

Ready to build your foundation of clarity? The first step in any successful process improvement journey is documentation. Build a Guide turns this critical task from a tedious chore into a simple, automated workflow. Capture any process with a screen recording, and our platform instantly transforms it into an interactive, step-by-step guide you can share, edit, and embed anywhere. Start creating your single source of truth today at Build a Guide and accelerate your path to operational excellence.