January 13, 2026

7 Real-World Process Improvement Example Breakdowns for 2026

Unlock efficiency with our deep dive into a real process improvement example for every business function. See before/after metrics and actionable steps.

It’s easy to talk about 'improving processes,' but what does it actually look like in practice? The difference between a struggling team and a high-performing one often comes down to well-defined, efficient workflows. Without them, tasks fall through the cracks, deadlines are missed, and both employee and customer satisfaction plummet. This isn't about vague theories or abstract business jargon; it's about making tangible changes that save time, reduce costs, and eliminate friction from daily operations.

This article moves beyond theory to dissect seven real-world process improvement example scenarios, showing you the exact strategies used to fix broken workflows. We are not just sharing success stories; we are providing a strategic playbook. For each detailed example, we will break down:

The Initial Problem: The specific pain points and inefficiencies that prompted the change.

Step-by-Step Actions: The precise tactics and frameworks, like Kaizen or Lean Six Sigma, that were implemented.

Before & After Metrics: The measurable results that prove the effectiveness of the new process.

Actionable Takeaways: Replicable strategies and checklists you can apply to your own organization.

We'll cover diverse areas, from streamlining customer support ticket handling and optimizing client onboarding to refining complex software release workflows. Furthermore, we’ll explore how to solidify these gains by documenting the new standard operating procedure (SOP). Properly documented processes are the key to ensuring improvements stick and your team stays aligned, turning a one-time fix into a new, higher standard of operation. Let’s dive into the examples.

1. Lean Six Sigma Process Optimization

Lean Six Sigma is a powerful, data-driven methodology that combines two proven process improvement frameworks. Lean focuses on maximizing customer value while minimizing waste, and Six Sigma aims to reduce process variation and eliminate defects. Together, they create a systematic approach for achieving operational excellence.

This method stands out as a top-tier process improvement example because it provides a structured, empirical framework called DMAIC (Define, Measure, Analyze, Improve, Control) to solve complex problems. It moves beyond guesswork, forcing teams to use data to pinpoint the root causes of inefficiency and validate the impact of changes.

How It Works: The DMAIC Framework

The core of Lean Six Sigma is the DMAIC cycle, a five-phase project management system.

Define: Clearly identify the problem, project goals, and customer requirements.

Measure: Collect data to establish a baseline for current process performance.

Analyze: Use statistical analysis to identify the root cause of defects and variations.

Improve: Develop, test, and implement solutions that address the root cause.

Control: Implement monitoring systems and standardized procedures to sustain the gains.

Strategic Insight: The strength of DMAIC is its insistence on data-backed decisions. By establishing a performance baseline in the "Measure" phase, you can definitively prove the ROI of your improvement efforts in the "Control" phase, making it easier to get buy-in for future projects.

Real-World Success Stories

General Electric (GE): Under CEO Jack Welch, GE famously adopted Six Sigma, reportedly saving the company billions by reducing defects and streamlining manufacturing and service operations.

Amazon: The e-commerce giant uses Lean Six Sigma principles to optimize its fulfillment center operations, from inventory management to package routing, enabling its rapid delivery promises.

Healthcare: Hospitals apply this method to streamline patient intake and discharge processes, reducing wait times and improving patient satisfaction scores.

Actionable Tips for Implementation

Start Small: Begin with a single, well-defined pilot project. Choose a process with clear pain points and measurable outcomes to demonstrate value before a company-wide rollout.

Assign Ownership: Designate a "Process Owner" for the improved workflow. This person is responsible for monitoring performance and ensuring the new standard operating procedure (SOP) is followed.

Document and Standardize: Immediately after completing the "Improve" phase, document the new process. Using a tool like Build a Guide helps create a clear, accessible SOP that becomes the single source of truth for the team.

Monitor and Refine: Use analytics to track how team members interact with the new documentation. If analytics show recurring hesitations or errors at a specific step, use that feedback to refine the procedure and provide further training.

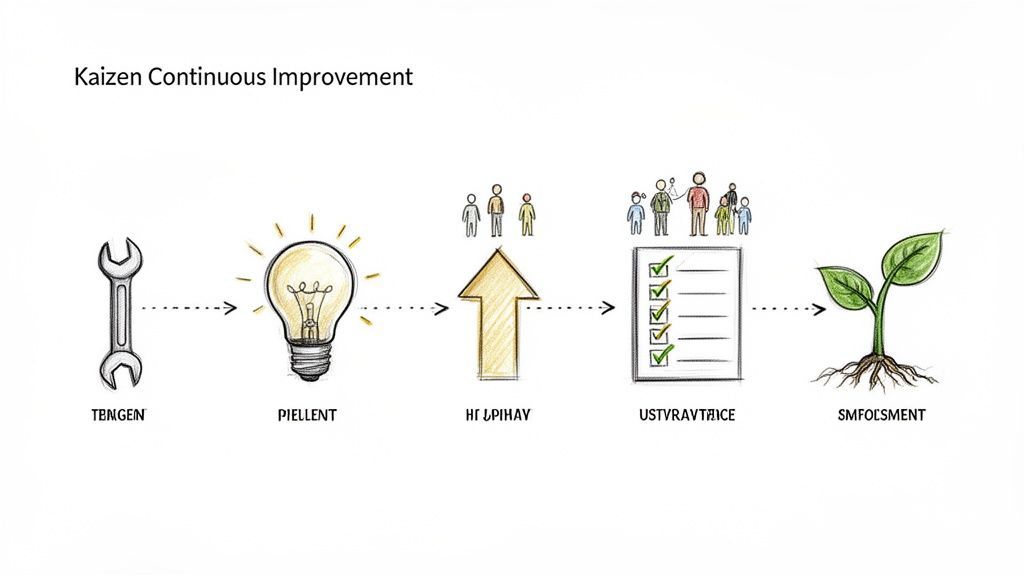

2. Kaizen and Continuous Improvement Culture

Kaizen is a Japanese philosophy that translates to "change for the better" or "continuous improvement." It is a foundational process improvement example that focuses on making small, incremental changes consistently over time. Unlike large-scale, disruptive projects, Kaizen empowers every employee, from the front line to the C-suite, to identify and solve inefficiencies within their own workflows.

This approach builds a powerful, bottom-up culture of ownership and momentum. It's particularly effective for teams that need to adapt quickly without the overhead of heavyweight transformation programs. The core idea is that many small improvements, compounded over time, lead to massive gains in quality, efficiency, and employee engagement.

How It Works: The PDCA Cycle

Kaizen is often implemented through the PDCA (Plan-Do-Check-Act) cycle, a simple yet effective framework for iterative improvement.

Plan: Identify an opportunity for improvement and plan a small, testable change.

Do: Implement the change on a small scale.

Check: Observe and collect data to see if the change had the desired effect.

Act: If the change was successful, standardize it and implement it more broadly. If not, begin the cycle again with a new plan.

Strategic Insight: The power of Kaizen lies in its accessibility. By focusing on small, low-risk changes, it lowers the barrier to participation. Anyone can suggest a tweak, making process improvement a daily habit rather than a sporadic, top-down initiative.

Real-World Success Stories

Toyota: The Toyota Production System is the most famous application of Kaizen. Factory workers are empowered to stop the production line to fix issues, leading to decades of continuous refinement in quality and efficiency.

Tech Startups: Agile and Scrum methodologies incorporate Kaizen principles through weekly retrospectives, where teams discuss what went well, what didn't, and identify small process tweaks to implement in the next sprint.

Customer Support: Teams use Kaizen to iterate on ticket resolution workflows. A support agent might suggest a new canned response or a small change to a knowledge base article, which is quickly tested and adopted if proven effective.

Actionable Tips for Implementation

Create a Suggestion System: Implement a simple way for anyone to submit ideas, whether it's a digital form, a Slack channel, or a physical suggestion box.

Hold Daily Huddles: Start each day with a brief 10-minute stand-up meeting to discuss ongoing work and identify any immediate "pebbles in the shoe" that can be removed.

Document and Share: When an improvement is validated, immediately update the relevant Standard Operating Procedure (SOP). Using a collaborative tool like Build a Guide allows teams to co-edit processes in real time, ensuring the documentation is always current.

Celebrate Small Wins: Publicly acknowledge and celebrate the people who contribute successful ideas. This reinforces the desired culture and encourages further participation. For more ideas, you can explore several process improvement best practices.

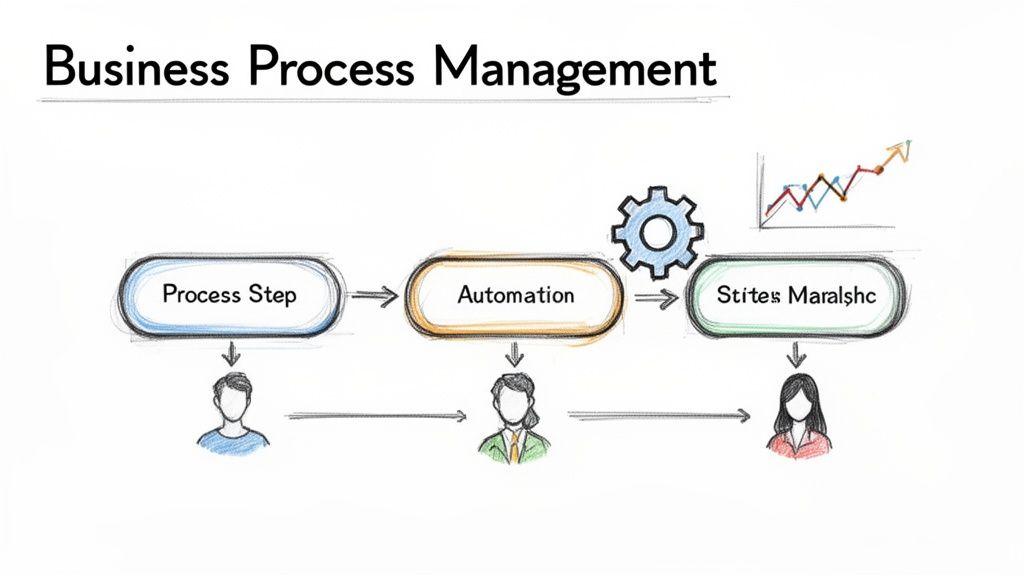

3. Business Process Management (BPM) and Workflow Automation

Business Process Management (BPM) is a disciplined approach to discovering, modeling, analyzing, measuring, improving, and optimizing business workflows. It moves beyond a single project and treats process improvement as a continuous, strategic discipline. The goal is to align every process with the organization's strategic goals, often by leveraging technology and automation.

This methodology is a crucial process improvement example because it provides a holistic view of how work gets done across an organization. Instead of fixing isolated tasks, BPM focuses on optimizing end-to-end workflows, identifying bottlenecks, and automating repetitive, low-value activities to free up human talent for more strategic work.

How It Works: The BPM Lifecycle

BPM operates as a continuous cycle, ensuring processes evolve with the business.

Design & Model: Visualize and map the current ("as-is") process to understand how it works. Then, design the ideal future ("to-be") process.

Execute: Implement the redesigned process, often with the help of BPM software or automation tools that manage tasks, rules, and data flow.

Monitor: Track process performance using key metrics like cycle time, cost per transaction, and error rates.

Optimize: Analyze performance data to identify new bottlenecks or improvement opportunities, and then restart the cycle.

Strategic Insight: The power of BPM lies in its ability to make processes explicit and repeatable. By modeling workflows, you expose hidden inefficiencies and create a blueprint for automation that ensures consistency and scalability, especially in functions like client onboarding or support.

Real-World Success Stories

Salesforce: The CRM giant uses its own platform to automate complex sales and marketing workflows. It automates lead scoring, routing, and follow-up sequences, ensuring a consistent and efficient process for its massive sales teams.

Insurance Companies: Many insurers use BPM to automate the claims processing workflow. The system can automatically validate claim data, check policy rules, and route claims to the right adjusters, drastically reducing processing times.

HR Departments: BPM automates employee onboarding by triggering a series of tasks-from sending the offer letter to provisioning IT equipment and scheduling orientation-once a candidate is marked as hired.

Actionable Tips for Implementation

Map Before You Act: Always start by mapping the current state ("as-is") process. This baseline reveals the actual pain points and prevents you from automating an already inefficient workflow.

Target Repetitive Tasks: Identify high-volume, repetitive, and rule-based tasks for your first automation project. These offer the quickest wins and the highest ROI.

Document the Automated Flow: Once a process is automated, use a tool like Build a Guide to create a visual SOP. This helps employees understand how the new automated system works and their role within it. For a great starting point, check out this workflow documentation template.

Monitor Adoption: Integrate data from your BPM tool with documentation analytics. This allows you to see if teams are following the new process and where they might need additional training or clarification.

4. Standard Operating Procedures (SOPs) and Documentation Systems

Standard Operating Procedures (SOPs) are detailed, written instructions that describe how to perform specific tasks or processes within an organization. A robust SOP system ensures consistency, reduces training time, minimizes errors, and creates institutional knowledge that survives employee turnover.

This approach is a foundational process improvement example because it formalizes best practices. SOPs don't just improve a process; they capture the improved state, providing a baseline for future optimization and ensuring that hard-won efficiencies are not lost to inconsistency or employee turnover. They transform tribal knowledge into a scalable, corporate asset.

How It Works: The Documentation Cycle

A successful SOP system is a living ecosystem, not a one-time project. It follows a continuous documentation cycle.

Capture: Observe and record the process as it is actually performed by experienced team members.

Standardize: Analyze the captured steps to define the single most efficient and effective workflow, removing redundant or unnecessary actions.

Document: Create a clear, accessible guide with visuals, checklists, and step-by-step instructions.

Distribute & Train: Make the SOP easily available to all relevant team members and integrate it into training and onboarding programs.

Monitor & Refine: Use feedback and analytics to identify points of confusion or outdated steps, then update the documentation accordingly.

Strategic Insight: The true power of an SOP system is realized when it becomes a "single source of truth." When everyone from a new hire to a seasoned veteran refers to the same guide, you eliminate process variation at its root, leading to predictable, high-quality outcomes.

Real-World Success Stories

McDonald's: The fast-food giant’s global success is built on an unparalleled SOP system. Every task, from flipping burgers to cleaning the shake machine, is meticulously documented to ensure a consistent customer experience at every location worldwide.

Call Centers: High-performing support centers use detailed SOPs for handling common customer inquiries. This ensures every agent provides accurate, brand-aligned responses, dramatically improving First Call Resolution (FCR) rates and customer satisfaction.

Manufacturing: ISO-certified facilities rely on exhaustive SOPs for production and safety protocols. This not only guarantees product quality and consistency but also minimizes workplace accidents and ensures regulatory compliance.

Actionable Tips for Implementation

Start with High-Impact Processes: Don't try to document everything at once. Begin with processes that are high-frequency, complex, or directly impact customer experience to see the quickest ROI.

Use Visuals Heavily: A picture is worth a thousand words. Use screenshots, short video clips, and annotated images to make instructions instantly understandable and reduce cognitive load.

Involve the End-Users: Collaborate with the employees who actually perform the process. They can provide invaluable insights into overlooked steps and real-world challenges, ensuring the final SOP is practical and accurate.

Treat SOPs as Living Documents: Processes evolve, and so should your documentation. Schedule regular reviews (e.g., quarterly) and establish a clear channel for team members to suggest updates as they discover better methods. To dive deeper, explore this comprehensive guide to standard operating procedure templates.

5. Total Quality Management (TQM) and Quality Improvement

Total Quality Management (TQM) is a comprehensive organizational management philosophy centered on the continuous improvement of products, services, and processes. It engages all levels of an organization, from leadership to the front line, in a shared commitment to enhancing customer satisfaction and organizational performance.

This approach stands out as a critical process improvement example because it instills a culture of quality, rather than treating quality as a final inspection step. TQM's core principle is that every employee is responsible for quality, which drives proactive problem-solving and systemic enhancements across all business functions, not just manufacturing or operations.

How It Works: The TQM Philosophy

TQM is built on several key principles that guide an organization's behavior and decision-making.

Customer Focus: All activities and improvements are driven by the needs and expectations of both internal and external customers.

Total Employee Involvement: Everyone in the organization participates in achieving quality goals, fostering a sense of ownership and empowerment.

Process-Centered: TQM views work as a series of interconnected processes, focusing on refining these steps to reduce variation and improve outcomes.

Continuous Improvement (Kaizen): The philosophy emphasizes an ongoing effort to make incremental improvements to processes, believing that small changes over time lead to significant gains.

Data-Driven Decisions: Like Six Sigma, TQM relies on data and systematic analysis to identify quality gaps and measure the impact of changes.

Strategic Insight: TQM's power lies in its cultural impact. By making quality everyone's job, you decentralize process improvement. This creates a highly responsive organization where team members are empowered to flag inefficiencies and suggest improvements directly, rather than waiting for a top-down mandate.

Real-World Success Stories

Xerox: In the 1980s, facing intense competition, Xerox launched its "Leadership Through Quality" TQM program. This initiative empowered employees to improve processes, dramatically enhancing product quality and helping the company regain its market leadership.

Toyota: The Toyota Production System is a prime example of TQM in action. Its focus on continuous improvement (Kaizen) and respect for people has made it a global benchmark for manufacturing excellence and quality.

Healthcare: Hospitals use TQM principles to improve patient safety and outcomes. By analyzing processes like medication administration or surgical procedures, they systematically reduce errors and enhance the quality of care.

Actionable Tips for Implementation

Define Quality Standards: For each key process, clearly define what "quality" means. Establish specific, measurable standards and metrics, such as a target customer satisfaction score or a maximum ticket resolution time.

Involve Everyone: Create cross-functional teams to brainstorm quality improvements. A support agent often has the best insight into customer pain points, so their input is invaluable for improving documentation or product workflows.

Create Feedback Loops: Use customer feedback to identify quality gaps. Document customer complaints and their resolutions, then analyze trends to update SOPs and prevent recurrence.

Document and Monitor: As you improve a process, document the new standard procedure in a tool like Build a Guide. Use its engagement analytics to measure how well the new SOP meets user needs, ensuring the documentation itself is of high quality and effectively supports the team.

6. Agile Process Improvement and Sprint-Based Optimization

Agile is a process improvement methodology that champions iterative development and continuous feedback. Originating in software development, its principles are now widely applied to business processes. Instead of tackling large-scale changes in one massive project, Agile breaks down improvement efforts into small, manageable cycles called "sprints."

This approach stands out as a premier process improvement example for dynamic environments where requirements frequently change. It allows teams to implement, test, and refine procedures quickly, ensuring that processes evolve in real-time with customer needs and market feedback, rather than becoming outdated before they are even fully implemented.

How It Works: The Sprint Cycle

The core of Agile process improvement is the sprint, a short, time-boxed period during which a team works to complete a specific set of improvements.

Prioritize: The team identifies and prioritizes a list of potential process improvements in a "backlog," often based on customer impact or internal friction.

Plan: At the start of a sprint (typically 1-4 weeks), the team selects a small number of high-priority items from the backlog to work on.

Execute: The team implements the changes, which could involve rewriting an SOP, reconfiguring a tool, or testing a new workflow.

Review & Retro: At the end of the sprint, the team demonstrates the changes and holds a "retrospective" to discuss what went well, what didn't, and how to improve the next sprint.

Strategic Insight: Agile's strength is its speed and adaptability. By working in short sprints, you create a system for continuous, incremental improvement. This de-risks major changes by allowing you to test ideas on a small scale and pivot quickly based on real-world results.

Real-World Success Stories

Spotify: The music streaming giant famously organized its teams into "squads, tribes, chapters, and guilds," applying Agile principles beyond software to foster autonomy and rapid innovation in all business functions.

Atlassian: The company uses its own Agile tools (like Jira) to continuously improve everything from product development cycles to customer support ticket handling, treating operational processes like a product that is constantly being iterated upon.

Marketing Agencies: Many agencies run marketing campaigns in two-week sprints, allowing them to test messaging, analyze performance data, and rapidly optimize ad spend and content strategy instead of sticking to a rigid quarterly plan.

Actionable Tips for Implementation

Create a Process Backlog: Start a shared list where any team member can add ideas for process improvements. Prioritize this backlog based on potential impact and effort required.

Run Dedicated Improvement Sprints: Schedule a recurring, short sprint (e.g., two days per month) where the team's sole focus is tackling items from the process backlog.

Use Feedback to Fuel the Next Cycle: At the end of each sprint, review analytics and user feedback. If analytics from a tool like Build a Guide show users are still stumbling on a newly updated SOP, make that a priority for the next sprint.

Document Incrementally: Don't wait for a process to be "perfect" before documenting it. Use Build a Guide to quickly capture the new workflow during the sprint. The real-time collaboration features allow the team to refine the documentation as they go.

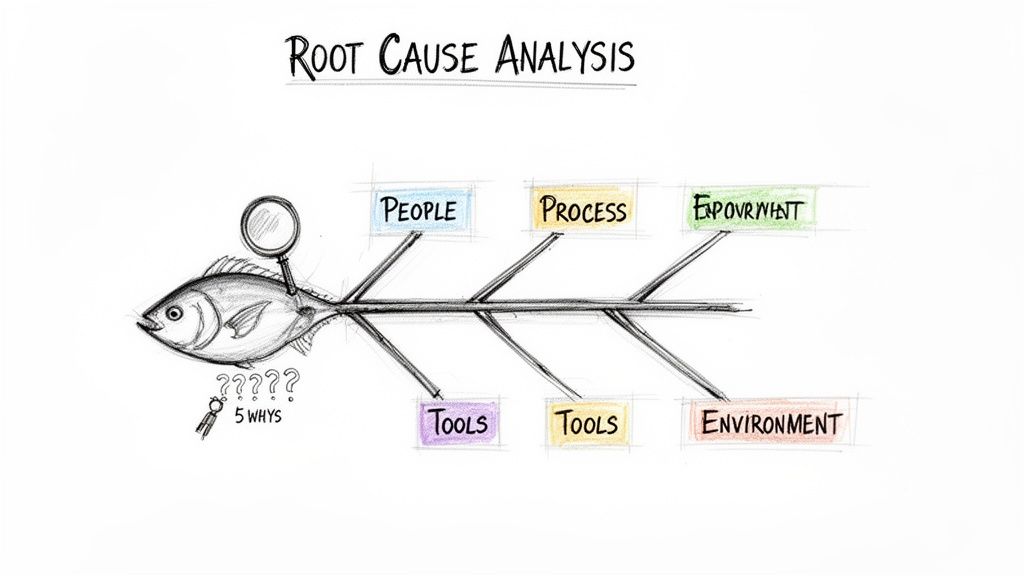

7. Root Cause Analysis (RCA) and Problem-Solving Frameworks

Root Cause Analysis (RCA) is a systematic method for identifying the underlying causes of problems rather than just treating the immediate symptoms. By focusing on the "why" behind an issue, teams can implement solutions that prevent recurrence, leading to more resilient and efficient processes.

This approach is a critical process improvement example because it prevents "Band-Aid" fixes that fail to address the core issue. Instead of simply training an employee who made a mistake, RCA investigates why the mistake was possible in the first place, perhaps revealing a confusing SOP, a faulty tool, or a gap in the process design itself.

How It Works: Common RCA Methods

RCA isn't a single technique but a collection of structured problem-solving frameworks. The most common include:

The 5 Whys: A simple but powerful method of repeatedly asking "Why?" to drill down past surface-level symptoms and uncover the true origin of a problem.

Fishbone (Ishikawa) Diagram: A visual tool used to brainstorm and categorize potential causes of a problem, often grouped into categories like People, Process, Technology, and Environment.

Fault Tree Analysis: A top-down deductive analysis where a specific failure is traced back through a series of logical steps to identify its potential causes and their probabilities.

Strategic Insight: The value of RCA is its ability to transform reactive problem-solving into proactive process improvement. By understanding the root cause of a single customer complaint or production defect, you can update your standard operating procedures to eliminate that entire class of problems for everyone in the future.

Real-World Success Stories

Toyota: The automaker famously integrated the "5 Whys" into its Toyota Production System. When a machine stopped, operators were trained to ask "why" five times to find the root cause (e.g., a clogged filter) rather than just restarting the machine.

Aviation Industry: Following any safety incident, aviation authorities conduct exhaustive RCAs to understand the chain of events. These findings lead to updated maintenance protocols, pilot training, and aircraft design, making air travel one of the safest modes of transportation.

Tech Companies: When customer churn spikes, product teams use RCA to analyze user behavior data and support tickets. This helps them identify if the cause is a recent feature change, a performance bug, or a gap in the onboarding documentation.

Actionable Tips for Implementation

Use Data to Find Starting Points: Analyze support ticket trends or customer feedback to identify recurring issues. These are prime candidates for a formal RCA session.

Involve Cross-Functional Teams: Conduct a "5 Whys" or Fishbone session with people who actually perform the process. Include team members from different departments to get a holistic view of the problem.

Update SOPs Based on Findings: The output of an RCA should be a change to a process. If the analysis reveals a step in your documentation is consistently misunderstood, use a tool like Build a Guide to rewrite and clarify it with screenshots or video.

Track and Validate the Fix: After implementing a change based on your RCA, monitor the data. Track whether the frequency of the original problem has decreased to confirm your solution was effective and delivered a positive ROI.

7-Method Process Improvement Comparison

Approach | 🔄 Implementation Complexity | ⚡ Resource Requirements & Speed | 📊 Expected Outcomes | 💡 Ideal Use Cases | ⭐ Key Advantages |

|---|---|---|---|---|---|

Lean Six Sigma Process Optimization | High — DMAIC, statistical methods, certified practitioners required | High resources & time up front; slow initial rollout, strong long-term efficiency | Measurable KPI improvements; reduced variation and defects; scalable gains | Large operations, manufacturing, complex cross-functional processes | ⭐⭐⭐⭐ Quantifiable, sustainable reductions; strong standardization |

Kaizen and Continuous Improvement Culture | Low–Medium — simple cycles but needs cultural reinforcement | Low resource intensity; quick small wins delivered continuously | Incremental efficiency gains; higher employee engagement over time | SMBs, distributed/remote teams, frontline operations | ⭐⭐⭐ Engages employees; low-cost, sustainable improvements |

BPM and Workflow Automation | High — process modeling, integrations, technical expertise required | High tool and implementation cost; automates repetitive work for fast runtime efficiency | Major reduction in manual tasks; real-time visibility and bottleneck detection | Agencies, SaaS, customer success, high-volume transactional workflows | ⭐⭐⭐⭐⭐ Scales efficiently; reduces manual error; strong monitoring |

SOPs and Documentation Systems | Medium — time-consuming to create; requires governance and versioning | Moderate resources; initial effort high, speeds onboarding and consistency | Consistent operations, reduced training time, compliance readiness | Any organization needing repeatability, onboarding, or compliance | ⭐⭐⭐⭐ Foundational: captures knowledge, shortens training, enables quality control |

Total Quality Management (TQM) and Quality Improvement | High — organization-wide cultural change and leadership commitment | Significant long-term investment; slow ROI but durable quality gains | Broad quality improvements; fewer defects and higher customer satisfaction | Large enterprises, regulated industries, customer-centric organizations | ⭐⭐⭐⭐ Holistic quality culture; long-term reputation and reliability gains |

Agile Process Improvement and Sprint-Based Optimization | Medium — requires Agile practices and experienced facilitators | Moderate resources; rapid short-cycle improvements and frequent updates | Fast validated improvements; continuous SOP iteration and reduced risk | Fast-moving teams, SaaS, startups, product and support teams | ⭐⭐⭐⭐ Rapid adaptation; prioritizes high-impact changes with frequent feedback |

Root Cause Analysis (RCA) and Problem-Solving Frameworks | Medium–High — structured investigation methods (5 Whys, fishbone) | Moderate resources; time-intensive analysis but precise fixes | Targeted elimination of recurring problems; improved SOP accuracy | Incident response, safety-critical sectors, recurring defect resolution | ⭐⭐⭐⭐⭐ Identifies true causes; prevents recurrence and informs effective SOP updates |

Making Improvements Stick: Your Next Steps

The journey through each process improvement example, from streamlining support tickets to optimizing client deliverables, reveals a powerful, unifying truth: successful change is intentional, measurable, and sustainable. It’s not about a single moment of inspiration but a structured commitment to finding a better way of working. We've explored diverse methodologies, from the data-driven rigor of Lean Six Sigma to the incremental, culture-shifting power of Kaizen.

Across every scenario, a clear pattern emerges. The most impactful improvements don't just solve a problem; they establish a new, higher standard of performance. This new standard prevents the team from reverting to old, inefficient habits and creates a stable foundation for future growth. Without this final step, even the most brilliant optimization effort is at risk of becoming a temporary fix rather than a permanent upgrade.

Core Principles for Sustainable Process Improvement

As you reflect on the examples provided, several key principles stand out. These are the strategic pillars that support any successful initiative, regardless of the specific methodology you choose.

Data is Your Compass: Every meaningful process improvement starts with measurement. Whether you're tracking ticket resolution times or new hire productivity, having a clear "before" metric is non-negotiable. This data not only validates the problem but also provides the undeniable proof that your solution worked.

Small Wins Fuel Big Momentum: The Kaizen philosophy teaches us that monumental change is often the result of many small, consistent steps. Don't underestimate the power of a minor tweak to a workflow or a small automation in a repetitive task. These incremental gains build confidence and cultivate a culture where everyone is empowered to look for opportunities to improve.

Empowerment Drives Adoption: The teams closest to the work often have the best insights. A top-down mandate for change can be met with resistance, but a collaborative approach that involves frontline employees in a root cause analysis or solution design fosters a sense of ownership. When your team helps build the new process, they are far more likely to embrace and defend it.

Your Action Plan: From Example to Execution

Moving from inspiration to implementation is the most critical step. The process improvement example you found most compelling can serve as your blueprint. Here’s how to translate what you've learned into concrete action and ensure your hard-won gains are locked in for the long term.

Identify Your Target: Select one specific, high-friction process within your organization. Is it the chaotic onboarding of a new client? The endless back-and-forth of content approvals? Choose a single, well-defined problem to tackle first.

Establish Your Baseline: Before you change anything, document the current state. How long does it take? How many errors occur? What is the tangible cost of this inefficiency? Use the metrics from our examples as a guide to establish your own KPIs.

Engage the Stakeholders: Assemble the team that lives with this process every day. Use frameworks like Root Cause Analysis to dig deeper than the surface-level symptoms and uncover the core issue. Brainstorm and map out a revised, optimized workflow together.

Document the New Standard: This is where improvement becomes permanent. A verbal agreement or a messy email chain is not enough. The new process must be documented in a clear, accessible, and easy-to-follow Standard Operating Procedure (SOP). This is the single source of truth that will guide training, ensure consistency, and prevent process decay.

Ultimately, mastering process improvement is about building organizational muscle. Each successful project, no matter how small, strengthens your team’s ability to adapt, innovate, and excel. By transforming a theoretical process improvement example into a documented, adopted reality, you are not just fixing a workflow; you are building a more resilient, efficient, and competitive organization.

Ready to turn your optimized workflows into living, actionable guides? Build a Guide makes it simple to document your new processes, create interactive SOPs, and ensure your team adopts improvements consistently. Stop letting good processes fade away and start building your single source of truth today at Build a Guide.