January 14, 2026

Process management strategy: Build a Winning Operational Framework

Master a process management strategy with practical steps to map workflows, measure performance, and boost efficiency.

A process management strategy is the deliberate, systematic way a company designs, manages, and improves how work gets done. Think of it as the master blueprint that ensures everyone is creating value consistently, efficiently, and in a way that actually moves the business forward.

It’s about going from "this is just how we do things" to "this is the best way we do things—for now."

Why a Process Management Strategy Matters

Imagine trying to build a skyscraper without architectural plans. Different crews would work in silos, materials would be wasted, and the final structure would probably be unstable. A business without a process management strategy runs the same risks. It’s the framework that shifts your operations from reactive chaos to proactive control.

This isn’t just a modern buzzword. The idea has deep roots. When Henry Ford introduced the assembly line in 1913, he fundamentally changed manufacturing by proving that standardized, optimized workflows delivered incredible results. That core principle—that better processes lead to better outcomes—is still just as true today. If you're curious, you can explore the evolution of business process management to see how these foundational ideas grew over time.

At its heart, a process management strategy gives you a structured way to answer the big operational questions—not just what you do, but how you do it, ensuring every single action contributes to the company's mission.

The Shift from Instructions to a Living System

It’s easy to think process management is just about writing down instructions in a dusty binder.

But while documentation is part of it, a real strategy treats your processes as living, dynamic systems. They need to be constantly monitored, measured, and improved.

A great process management strategy doesn't just document what you do now; it builds a repeatable engine for becoming better at what you do tomorrow. It’s a commitment to perpetual refinement.

This means giving clear ownership to each workflow, defining metrics to see what’s working, and creating feedback loops for constant tuning. It's about building a culture where every team member is empowered to spot a bottleneck and suggest a better way. A well-designed strategy ensures that as your business scales and markets shift, your operations can adapt without breaking.

Key Benefits of a Formal Strategy

Putting a formal process management strategy in place delivers huge advantages that go way beyond just being "more efficient." It creates a solid foundation for growth you can actually sustain.

Here are the big wins:

Enhanced Consistency and Quality: Standardized processes cut down on variation and errors. That means more reliable outcomes and, ultimately, a better customer experience.

Improved Scalability: When workflows are documented and refined, bringing on new people and expanding into new markets becomes dramatically easier. You can grow without performance taking a nosedive.

Greater Agility: When you truly understand your processes, you can change them much faster. This lets you jump on new opportunities or respond to market shifts without hesitation.

Empowered Teams: Clear roles, responsibilities, and performance metrics give your teams the autonomy and information they need to own their work and succeed.

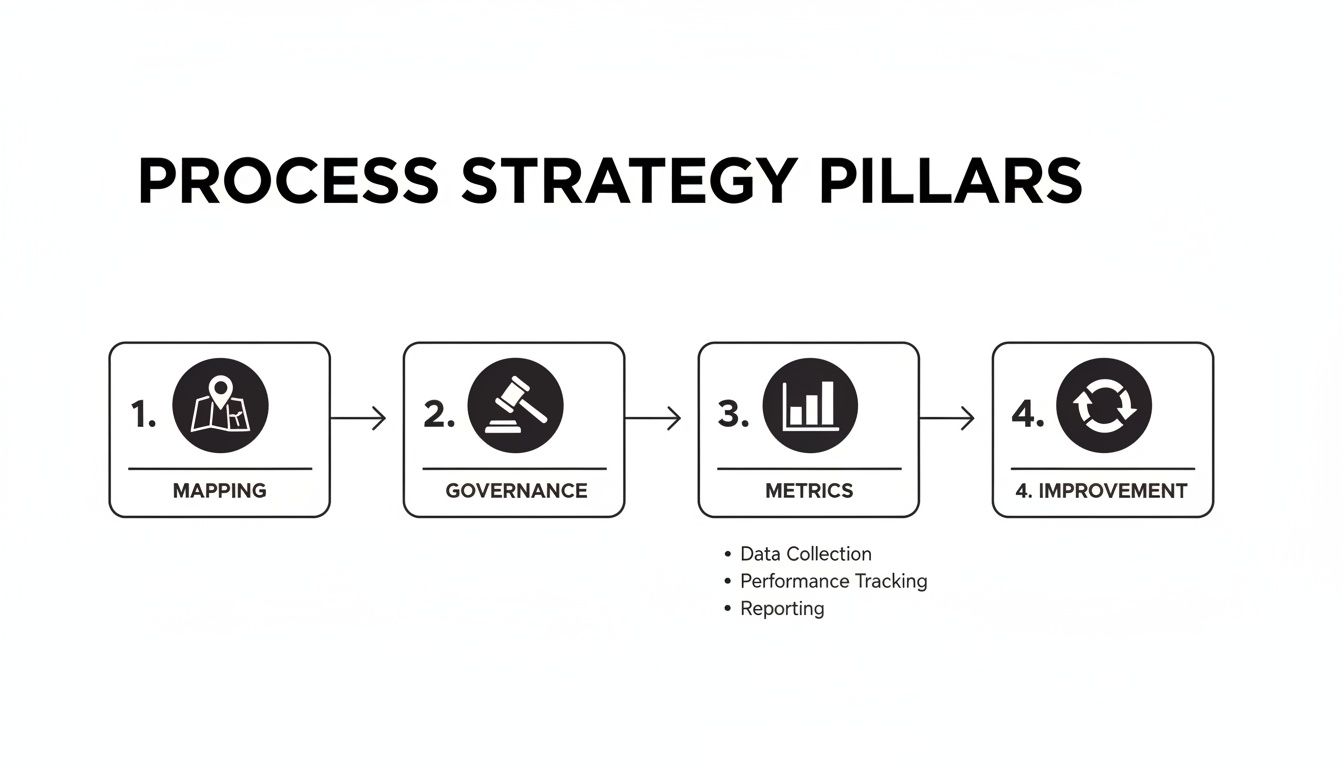

The Four Pillars of a Winning Strategy

A powerful process management strategy doesn't just appear out of thin air. It’s built on a solid foundation.

Just like a building needs structural columns to stand, your entire operational framework rests on four essential pillars. Together, they create a balanced, resilient system that turns fuzzy goals into real-world results.

Think of these pillars not as separate items on a checklist, but as interconnected parts of a single engine. Each one has a unique job, but they all work in harmony to drive your organization forward.

Let's break them down.

Pillar 1: Process Mapping and Documentation

You can't improve what you can't see.

This first pillar is all about making your workflows visible. Process mapping is the simple act of creating a visual blueprint of how work gets done, from start to finish. It’s like drawing a detailed map of a city's traffic system to finally spot where the jams always happen.

This visualization immediately uncovers redundancies, bottlenecks, and confusing handoffs that are often invisible in the day-to-day grind. The goal is to move beyond "tribal knowledge"—where crucial steps live only in a few key employees' heads—and create a single source of truth everyone can rely on.

Process documentation isn't about creating rigid rules to be stored in a dusty binder. It’s about creating clarity and a shared understanding of the best way to get work done right now, which serves as the baseline for all future improvements.

When every step, decision point, and responsible person is clearly documented, you lay the groundwork for consistency, easier training, and smarter optimization.

Pillar 2: Process Governance

A perfectly mapped process is useless if no one follows it. This is where process governance comes in.

This pillar establishes the rules, roles, and accountability needed to ensure your processes are executed consistently and managed effectively over time. Think of governance as the operating system for your processes.

It answers the critical questions:

Who owns this process? A designated process owner is responsible for its performance and improvement.

Who can approve changes? This prevents unauthorized or chaotic alterations to standardized workflows.

How will we handle exceptions? It defines a clear path for when things don't go according to plan.

How often will we review it? This ensures processes don’t become outdated and ineffective.

Without strong governance, even the best-designed processes will slowly degrade as people revert to old habits or create ad-hoc workarounds. It provides the structure and discipline needed for long-term success.

Pillar 3: Performance Metrics and KPIs

The third pillar is all about measurement.

If process mapping shows you what you're doing, performance metrics tell you how well you're doing it. To truly manage a process, you have to be able to quantify its performance using Key Performance Indicators (KPIs).

These aren't just vanity numbers; they are the vital signs that indicate the health of your operations. Your choice of metrics should directly reflect what you're trying to achieve, whether it's speed, cost-efficiency, or quality.

Common Process Metrics Include:

Cycle Time: The total time from the start of a process to its end. For example, the time from a customer placing an order to when it is shipped.

Error Rate: The percentage of outcomes that contain defects or require rework. A high error rate in a manufacturing line points to a quality control issue.

Throughput: The number of units that can be completed in a specific period. This measures the process's capacity.

Cost Per Transaction: The total cost associated with a single execution of the process.

Tracking these KPIs turns process management from a subjective exercise into a data-driven discipline, allowing you to prove ROI and make informed decisions.

Pillar 4: Continuous Improvement Frameworks

Finally, a process management strategy is never "done."

The fourth pillar embeds a culture of ongoing refinement into your organization. Continuous improvement is the commitment to systematically and perpetually seek out ways to make processes better. Instead of waiting for a major crisis, you proactively look for small, incremental gains.

This is often done using established frameworks like PDCA (Plan-Do-Check-Act) or Lean methodologies. These frameworks provide a structured approach for identifying an opportunity, testing a solution, analyzing the results, and standardizing the new, better way. For a deeper look at this pillar, you can explore some foundational process improvement best practices that successful organizations rely on.

This pillar shifts your team's mindset from "this is how we've always done it" to "how can we do this better tomorrow?" It transforms your strategy from a one-time project into a dynamic, ever-evolving capability.

The Four Pillars of a Process Management Strategy

To bring it all together, these four components are the non-negotiable building blocks of any successful process strategy. Each one plays a critical role in creating a system that is clear, accountable, measurable, and always getting better.

Pillar | Core Purpose | Key Actions |

|---|---|---|

Mapping & Documentation | To create visibility and a shared understanding of current processes. | Visualize workflows, identify steps, and create a single source of truth. |

Governance | To ensure consistency, accountability, and controlled change. | Assign process owners, define roles, and establish review cycles. |

Metrics & KPIs | To measure performance and make data-driven decisions. | Define KPIs, track performance, and analyze results to find opportunities. |

Continuous Improvement | To build a culture of ongoing optimization and adaptation. | Use frameworks like PDCA, test improvements, and standardize best practices. |

When you build your strategy on these four pillars, you're not just creating documents—you're building an operational engine designed for long-term growth and resilience.

How to Build Your Strategy Step by Step

Ready to move from theory to action? Building a process management strategy that actually works is a deliberate journey, not a sprint. It’s about creating a clear, phased approach that connects your biggest business goals to the day-to-day work your teams are doing.

This roadmap will walk you through five essential phases. Each step builds on the last, making sure your final strategy isn’t just a nice-looking document, but a practical, impactful framework built to last.

Let's start with the most critical first step: alignment.

Phase 1: Align with Strategic Business Objectives

Before you ever touch a single workflow, you have to connect your process efforts to the company's North Star. A process strategy that operates in a vacuum is destined to fail. Its entire purpose is to help the organization win—whether that means growing market share, keeping customers happy, or shipping products faster.

Start by asking the big-picture questions:

What are our company's top three strategic goals for the next year?

Which operational outcomes are non-negotiable for hitting those goals (e.g., faster delivery, lower costs, higher quality)?

How can improving our core processes directly move the needle on those outcomes?

This initial alignment gives your efforts a clear purpose and helps you get executive buy-in from day one. It reframes process improvement from a background operational task into a genuine business driver.

Phase 2: Identify and Prioritize Key Processes

Here’s a hard truth: not all processes are created equal. Trying to fix everything at once is a classic recipe for burnout and minimal impact. The real skill is figuring out which processes will give you the biggest return on your time and energy. You're hunting for workflows that are either high-value or high-pain.

First, create an inventory of your core business processes. You can group them into simple categories like customer-facing, operational, and support. Then, get ruthless about prioritizing them based on two factors:

Impact: How critical is this process to hitting your strategic goals or delivering value to customers?

Urgency: How broken is this process right now? Is it causing obvious bottlenecks, errors, or customer complaints?

The processes that land in that "high-impact, high-urgency" sweet spot are your first targets. Nailing these will generate visible wins and build the momentum you need for the whole initiative.

Phase 3: Document and Analyze Current State Workflows

With your priorities locked in, it’s time to get your hands dirty. You can't redesign a process you don't fully understand. This phase is all about mapping the "as-is" state of your chosen workflows—how they really work today, not how they’re supposed to work.

Grab the team members who actually do the work every day and walk through the process together, step-by-step. Document every action, decision point, handoff, and system they touch. The goal is to create a visual map that exposes the hidden realities of the workflow.

This isn't about blaming people for inefficiencies. It’s about creating a shared, objective picture of the current state so the team can collectively spot opportunities for improvement.

Once it's mapped, the analysis begins. Pinpoint the specific problems: bottlenecks where work piles up, redundant steps that add zero value, or long delays caused by waiting for information. This analysis gives you the raw material to build a smarter, leaner future state.

Phase 4: Redesign for Peak Performance

Now for the fun part: redesigning the process. Using the insights from your analysis, your team can start imagining a better way forward. The objective is to design a "to-be" process that is simpler, faster, and far more effective at delivering the intended outcome.

This redesign effort should be guided by a few core principles:

Eliminate Waste: Cut any step that doesn't add value from the customer's perspective.

Simplify: Consolidate steps, reduce handoffs, and make the workflow as straightforward as humanly possible.

Automate: Find the manual, repetitive tasks that a machine could do, freeing up your team for more valuable work.

This is where the four pillars of a strong strategy really come into play.

As the graphic shows, a successful strategy is a holistic one. Your process mapping, governance rules, performance metrics, and improvement cycles all have to work together to create a robust operational framework.

Work with stakeholders to draw up a new process map that reflects these improvements. This new design becomes the official blueprint for implementation, offering a tangible solution that directly fixes the pain points you uncovered earlier.

Phase 5: Create an Implementation and Communication Plan

A brilliant new process design on a whiteboard is worthless. The final phase is creating a detailed plan to bring it to life and—just as importantly—a plan to communicate it. This is where most strategies fall apart, usually due to a lack of good change management.

Your implementation plan needs to cover all the tactical details:

Timeline: What are the clear milestones and deadlines for rolling out the new process?

Resources: What tools, tech, and budget do you need to make the change happen?

Training: How will you get the team up to speed on the new way of working?

Metrics: How will you measure success and prove the new process is better than the old one?

Your communication plan is just as critical. You have to clearly sell the "why" behind the change to everyone involved. Explain the problems with the old way and the specific benefits the new process will bring—both to them and to the company. Securing buy-in from everyone, from frontline employees to your executive sponsors, is the key to a smooth and successful transition.

Putting Your New Strategy Into Action

A brilliant process management strategy on paper is just that—paper. Even the best blueprints don’t build houses on their own. The real test begins when your plans meet the messy reality of day-to-day work. This is the moment you have to bridge the gap between planning and doing, turning your carefully designed improvements into actual business results.

Instead of trying a risky, company-wide overhaul all at once, the smart move is to start small. Launching a pilot program in a controlled environment is the best way to test your redesigned processes without blowing anything up. This approach lets you work out the kinks, get real feedback, and prove the concept works on a limited scale.

Think of it like a dress rehearsal before opening night. By running the new workflow with just one team or on a single product line, you can spot unexpected problems and make adjustments without disrupting the entire company. A successful pilot builds confidence, creates internal champions for the change, and gives you the hard data you need to justify a bigger rollout.

Making Performance Visible Through Measurement

There’s a reason the old saying "what gets measured gets managed" has stuck around. It’s the absolute heart of making a new strategy work. Without clear metrics, you’re just flying blind. You have no way to know if your new processes are a genuine improvement or just a different way of doing the same old thing. This is where you connect your implementation directly back to the KPIs you defined earlier.

Setting up performance dashboards is the key to making this data visible and easy to understand. These dashboards should track the vital signs of your new process in real time.

A few key metrics you’ll want to watch during the rollout include:

Cycle Time Reduction: Is the new process actually faster than the old one?

Error Rate Decrease: Are you seeing fewer mistakes or less rework?

Throughput Increase: Can the team handle more volume in the same amount of time?

Team Adherence: Are people consistently following the new, standardized workflow?

Historically, the ability to measure process variation with this kind of precision was a massive leap forward. Statistical Process Control (SPC) first showed up back in 1920 when Walter A. Shewhart developed control charts to tell the difference between normal and unusual variations in factory output. This was really the birth of data-driven process management, a discipline that’s still evolving today.

Accelerating Rollout with Modern Tools

In the past, documenting new processes and training teams was a slow, manual chore. Today, technology has completely changed the game, making implementation faster and far more effective. This is where modern process management platforms become essential, closing the loop between strategy, documentation, and measurement.

Tools like Build a Guide, for example, can dramatically speed up this cycle. Instead of spending weeks writing manuals, you can just record a screen walkthrough of the new process. The platform’s AI then automatically turns that recording into a polished, step-by-step guide, complete with screenshots and instructions.

This screenshot shows how an AI-powered platform can instantly generate clear, visual Standard Operating Procedures (SOPs). This kind of instant documentation doesn’t just make training easier; it creates a single source of truth that’s simple to update and share. By using a dedicated standard operating procedure template, teams can ensure everything is uniform and clear from day one.

The real power of these tools is their ability to connect documentation directly to performance. Built-in analytics let you track guide views, completion rates, and user engagement, giving you direct insight into whether people are actually following the process.

This shifts process management from a guessing game to a data-driven discipline. You no longer have to wonder if people are following the new workflow—you have the data to prove it. This immediate feedback loop allows for quick adjustments, ensuring your strategy delivers on its promise of real, measurable gains in efficiency. And once your strategy is in motion, learning how to streamline business processes becomes the next logical step to maximize your results.

Using Technology to Simplify Process Management

A process management strategy sounds great in a meeting room, but it often falls apart the moment you try to put it into practice. Even the smartest plans can get bogged down by the sheer effort of writing everything down, training everyone, and making sure people actually stick to the new way of doing things.

This is where technology stops being a buzzword and starts being a force multiplier. It’s what turns a good plan on a whiteboard into a real, working system.

Imagine an operations manager, Alex, who's suddenly managing a remote team. Workflows that were second nature in the office are now a mess of conflicting versions and skipped steps. All that "tribal knowledge" that used to spread through casual conversations has vanished. It's a classic breakdown, but fixing it manually feels like an impossible task.

This is where modern tools come in. They don't just support the strategy; they bring it to life by tackling the biggest headaches head-on.

From Hours of Writing to Minutes of Recording

The first wall everyone hits is documentation. Traditionally, this meant spending endless hours writing manuals, taking screenshots, and formatting guides that were outdated almost as soon as they were finished. It was a massive time sink, and the final product was often a dense wall of text nobody wanted to read.

Modern platforms completely flip that around. With a tool like Build a Guide, Alex can just record a walkthrough of the correct process on screen. That's it. AI then instantly breaks the recording down into a step-by-step guide, complete with annotated screenshots and instructions.

What used to take an entire afternoon now takes about 15 minutes. This isn't just about saving time; it's about making your documentation agile. When a process changes, updating the guide is as simple as re-recording one small part, ensuring your source of truth is always current. You can check out different process documentation tools to see what fits your team's needs.

Eliminating Version Control Chaos

Alex’s next headache was version control. With guides saved on shared drives, desktops, and sent through email, no one ever knew if they were looking at the latest version. This chaos caused expensive mistakes and basically killed the whole point of standardization.

A centralized platform solves this by creating a single, living hub for all your SOPs.

Instead of digging through folders, team members can access a library of processes that are always up-to-date. When a guide gets an update, everyone gets the new version instantly. This removes all the ambiguity and ensures the whole team is working from the same playbook.

The right technology transforms process documentation from a static, fragmented archive into a dynamic, centralized knowledge base that empowers teams with instant clarity.

This single source of truth is the backbone of any good process strategy. To truly make things simple, you need the best software to document processes that can centralize everything and automate the busywork.

Gaining Real Insight into Adherence

The last piece of the puzzle is the most important: measurement. How does Alex know if the team is actually using the new guides? In the past, this was a total black box unless you were literally standing over someone's shoulder.

This is where modern tools provide the breakthrough with built-in analytics. Alex can finally see what’s really happening:

Who has viewed each guide: This confirms team members have actually opened the training materials.

Completion rates: Tracking who has finished a guide shows you where people might need a little extra help.

Where users get stuck: Engagement data can pinpoint confusing steps in a process, giving you direct feedback on what to improve.

This data finally closes the loop. Alex goes from hoping the team is following the process to knowing. Adherence stops being guesswork and becomes a measurable KPI, allowing for targeted coaching and continuous process improvement. Technology is what makes the strategy real, measurable, and ultimately, successful.

Common Questions About Process Management Strategy

As you start putting your operational framework together, a few questions always seem to pop up.

Getting straight answers to these common sticking points clears up confusion early, so small misunderstandings don't turn into major roadblocks later on.

This section tackles the most frequent questions we hear, with simple explanations to lock in the key ideas.

What Is the Difference Between Process and Project Management

This is probably the most common point of confusion, but the distinction is actually pretty simple—and critical.

Process management is all about repeatable, ongoing work designed for consistency. Think of fulfilling a daily customer order or onboarding a new employee. These are workflows that happen over and over again, and the goal is to make them as efficient and reliable as possible.

Project management, on the other hand, deals with temporary initiatives. Projects have a clear start, middle, and end. Launching a new website is a project. Opening a new office is a project. A project might be used to improve a process, but the process is the day-to-day workflow that continues long after the project team disbands.

How Often Should We Review Our Business Processes

There’s no magic number here. The right review frequency depends entirely on the process itself.

High-impact processes that directly touch customers or revenue—like your sales cycle or support ticket flow—might need a quarterly check-in to stay sharp. But stable, internal administrative processes, like submitting expense reports, can probably be reviewed just once a year.

A core part of a strong process management strategy is building a formal review schedule based on how important and volatile each process is.

A proactive review cadence is what separates a living strategy from a dusty binder of old procedures. It ensures your operations evolve with your business instead of holding it back.

This scheduled approach keeps your core operations from getting stale and guarantees you're always improving.

What Are the Biggest Implementation Challenges

Surprisingly, the biggest hurdles are almost always cultural, not technical. Picking the right software matters, but navigating the human side of change is where most initiatives succeed or fail.

The top implementation challenges usually come down to:

Resistance to Change: People are creatures of habit. A new process, even a better one, can feel disruptive and threatening to the way they've always worked.

Lack of Executive Buy-In: If leadership isn't visibly championing the changes, it’s tough to get the rest of the organization to take it seriously.

Poor Communication: Teams need to understand the "why." Without a clear explanation of the problems being solved, people will just see it as unnecessary extra work.

A successful strategy has to include a solid change management plan that tackles these human elements head-on.

Can Small Businesses Benefit from a Formal Strategy

Absolutely. In fact, you could argue a formal process strategy is more critical for a small business that wants to grow. It builds the operational foundation needed to scale without everything falling apart.

For a small team, a formal strategy creates consistency as new people are hired, breaking the dangerous dependency on "tribal knowledge" that lives inside one or two key employees' heads. It also directly improves the customer experience by standardizing how service is delivered.

Modern, accessible tools mean small businesses can implement a powerful strategy without an enterprise-level budget, making it more achievable and impactful than ever before.

Ready to stop documenting and start doing? Build a Guide turns your screen recordings into polished, AI-powered SOPs in minutes. Standardize your workflows, train your team, and measure adherence with a platform built to make your process management strategy a reality. Start creating your first guide today at https://buildaguide.app.